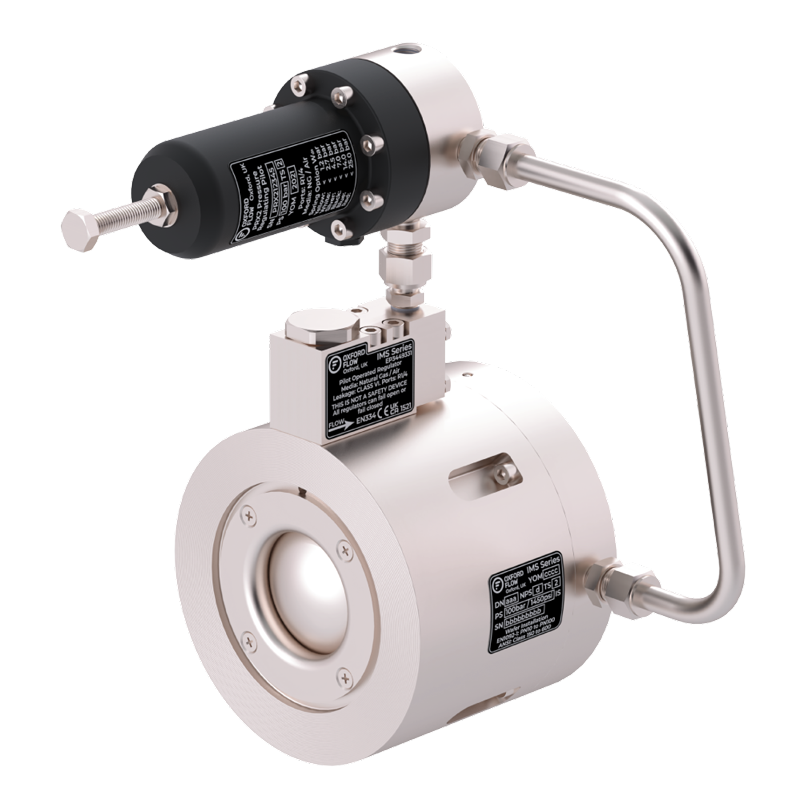

The IM-S gas regulator is the wafer variant in the Oxford Flow IM series. Requiring minimal maintenance and having an impressively small footprint, the popular IM-S regulator is hydrogen-ready and is helping gas networks prepare for the energy transition.

+/- 1% accuracy

Oxford Flow IM gas regulators are accurate to within +/- 1% of set point and class leading response times compared to conventional regulators. This enables customers to maintain excellent pressure control and stability in their process.

Up to 80% lighter

The compact IMS regulator is up to 80% lighter than some conventional, pilot-operated diaphragm regulators, eliminating the need for expensive lifting equipment during installation and maintenance. In conventional regulators, the diaphragm is the most common failure point.

Diaphragm eliminated

By eliminating the diaphragm, Oxford Flow has reduced the risk of regulator fatigue and failure. With a single moving part, the IM regulator minimises potential failures and the risk of unplanned maintenance – maximising efficiency and reducing operating costs.

Value Proposition

1

Diaphragm not required

the leading cause of instability in regulators

Benefit

Because the piston and pilot are primary sensors, it is inherently more stable and responsive at a wider range of flowrates.

Value proposition

Because the IM can be used across a wider range of flows, utilities can optimise piping, save money and provide more stable gas delivery to end-users.

2

Does not utilise an external stem

a primary source of methane emissions

Benefit

Does not require stem packing and frequent maintenance to meet emissions requirements.

Value proposition

Eliminates a frequent source of emissions, and reduces maintenance OPEX.

3

Minimal internal components and a single moving part

compared to conventional regulators

Benefit

This reduces mechanical wear and simplifies maintenance.

Value proposition

Reduced mechanical wear increases operating life, and fewer parts means less downtime for and lower cost of repairs.

Insights

Insights